Services

A rapidly growing company in sourcing sector, SLINDO source and deliver fine chemicals both for vet and human, essential/fixed oils and packaging products to pharmaceutical, health-food and nutraceutical industries.

Driven by latest technological advancements in the industry, we are able to cater to any specification laid down by our clients.

Optimization of industrial and operational costs lead to outsourcing of all possible materials and processes. Global sourcing is one of the key components of our procurement strategy to leverage on low labor and material costs along with other business advantages.

Driven by latest technological advancements in the industry, we are able to cater to any specification laid down by our clients.

Optimization of industrial and operational costs lead to outsourcing of all possible materials and processes. Global sourcing is one of the key components of our procurement strategy to leverage on low labor and material costs along with other business advantages.

What We Do

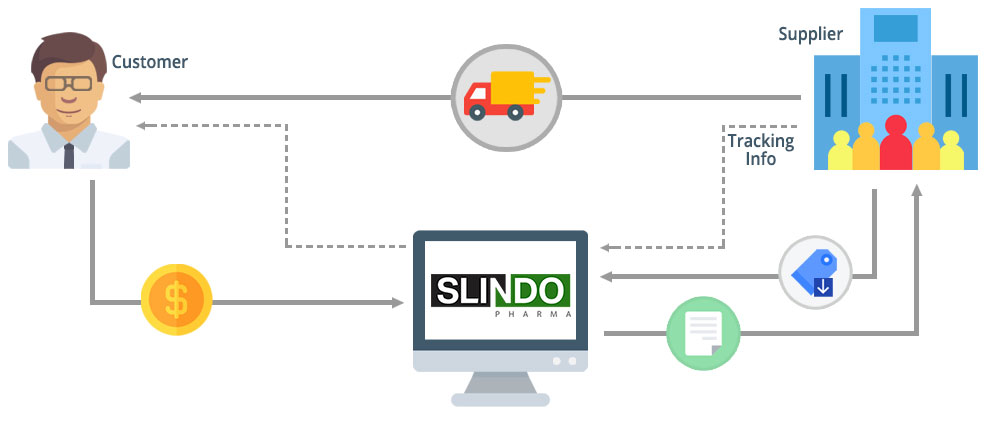

At SLINDO, we pride ourselves on delivering every link in the global supply chain and in delivering unsurpassed service at every stage. This starts with sourcing high quality products. We take a flexible and friendly approach; ensuring the appropriate finance and credit instruments are put in place; When it comes to transportation and logistics, Slindo recognises that mitigating all preventable risks is paramount.

Furthermore, we will help you negotiate a safe passage through the unfamiliar bureaucracy that awaits in any new market and gain the necessary clearances;

We at SLINDO have used knowledge gained from our long-term experience as professionals to create a stable foundation, modeled for success, based on our unique business philosophy and never erring guiding principles.

Business Sectors

- Bulk API supply for the manufacture of licensed medicines, managing long supply chains and lead-times through to timed local deliveries

- Product; technical and regulatory support for New Product Development

- Second source or alternative source with proactive change control management

- Low volume API supply for Specials manufacturers

- R&D quantities for Contract Research Organizations and Formulation Development

- Pilot or Small-scale production for Process Validation or Clinical Trials Manufacture

The basic requirements of Good Distribution Practice underpin all of the above, but we have direct experience and understanding of the specific demands and requirements of each sector to ensure a smooth process.

Individual Customization

Slindo responds quickly to client needs not only to ensure smooth processing of orders but also ascertain special requirements of each client are respected according to individual needs.

Made to Order:

- Specific Material Requirements

- Special Packing Materials

- Computer-Aided Product Certification

- Transport Documentation

- Regular Inspections by Certified Agencies

- GMP Documentation support

Strategic Sourcing

At Slindo we practice a continuous procurement process of discovering, prioritizing, improving, and re-evaluating sourcing activities that have helped best-in-class companies achieve substantial cost savings and other sourcing objectives.

Due Diligence

Are you single sourced and want to look at options for a second source? We can provide full due diligence on the available sources to help you identify not just who makes a product, but who is the best choice for you.

Supplier Selection

We have a decade of experience judging suppliers and informing our process of supplier selection based on a number of intangibles that are usually invisible from a company’s literature.

During this process, we will be able to foresee possible supplier-related risks while still in the early phase of the relationship. This process helps Slindo decide whether to accept this risk and create a contingency plan to deal with them head on, or simply choose to avoid doing business with certain suppliers if the risk is too big.

Selection Criteria

Slindo assess the following six areas in our self-evaluation questionnaire:

MANAGEMENT: Does the supplier have proper management systems in place and follows both internal and external standards? For example, we ask for quality management certifications, such as ISO9001, or ask about their company code of conduct. Basically, we want to guarantee the company is committed to being an honest partner.

SUSTAINABILITY: Here we will be looking for evidence that the supplier is financially sustainable and follows all appropriate safety rules. Depending on our customer’s primary areas of concern, we can also ask about social and environmental sustainability.

PRODUCT: We ask for evidence of the product test reports and certifications. We’ll also want to know how product quality is ensured, whether there is product development process and version handling process, etc.

PROCESS: Does the supplier have streamlined processes in place for handling nonconformities and managing sub-vendors ? We want to ensure that the supplier can target any production issues and fix them before they adversely affect your supply chain.

IMPROVEMENT: It’s important for us to see that there’s a continuous improvement process in place. The key here is to discern whether and to what extent suppliers cooperate with sub-vendors and/or customers.

COST: Finally, if they’re willing to share, we ask for information on their product cost structure. This may include the factors that affect their pricing, which can help you anticipate cost fluctuations down the line. We also ask them about their willingness to make an effort to reduce costs and share these savings with you, the buyer.